Heartwarming Tips About What Is A VFD Control Panel

VFD Panel Drawing What Is

Demystifying the VFD Control Panel

1. What Exactly Is a VFD Control Panel, Anyway?

Alright, let's break down the mystery surrounding the VFD control panel. Imagine you're driving a car. A VFD, or Variable Frequency Drive, is like the gas pedal for an electric motor. A VFD control panel is the central command center that houses all the necessary components to manage that "gas pedal." It's essentially a sophisticated electrical enclosure that allows you to control the speed of an AC motor by varying the frequency and voltage supplied to it.

Think of it this way: without a VFD control panel, your electric motor would only run at one speed — full blast! Which is fine for some things, like a blender pulverizing ice, but not so great for others, like a conveyor belt that needs to move at a snail's pace to allow for careful product placement. The VFD control panel gives you that fine-tuned control. Its the brains of the operation, ensuring everything runs smoothly and efficiently.

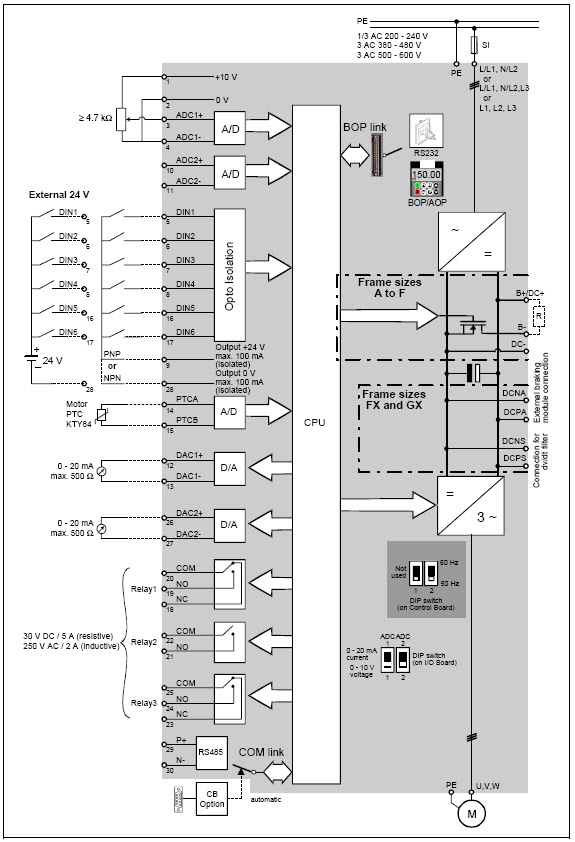

So, what's inside this magical box? Well, you'll typically find things like the VFD itself (the actual frequency drive), circuit breakers for protection, fuses, control wiring, and often a human-machine interface (HMI) — which could be a simple keypad or a fancy touchscreen — that lets you tell the VFD what to do. Think of it as the dashboard of your motor-controlling machine.

In simpler terms, the VFD control panel isn't just a box full of wires; it's a carefully engineered system designed to give you precise control over the speed and torque of your electric motors, saving energy and optimizing performance in the process. It's the difference between a wild, untamed motor and a finely tuned, efficient workhorse.

Why Would You Even Need One? Unveiling the Benefits

2. The compelling reasons to use a VFD Control Panel.

Okay, now that we know what a VFD control panel is, let's talk about why you'd want one. It's not just a fancy gadget; it's a game-changer for a lot of industrial and commercial applications. Imagine you're running a large pumping system for a building's water supply. Without a VFD, the pump runs at full speed, all the time, even if only a trickle of water is needed. That's a colossal waste of energy!

With a VFD control panel, you can precisely match the pump's speed to the actual water demand. This not only saves a ton of energy (reducing your electricity bill — cha-ching!) but also extends the life of the motor and pump. Less stress on the equipment means less wear and tear, and fewer costly repairs down the road. It's like driving a car at a consistent speed on the highway versus constantly slamming on the gas and brakes.

Another key benefit is improved process control. Think about a manufacturing line where products need to be filled to a precise level. A VFD control panel allows you to finely adjust the speed of the conveyor belt and filling machines, ensuring accurate and consistent results every time. This precision leads to higher quality products and reduced waste.

Beyond energy savings and precise control, VFDs offer benefits like reduced mechanical stress on equipment (think smoother starts and stops instead of jarring jolts), improved power factor (making your electrical system more efficient), and even the ability to communicate with other systems for automated control. So, whether you're running a massive industrial plant or a small commercial operation, a VFD control panel can be a surprisingly valuable investment.

VFD Control Wiring Diagram How To Wire A Variable Frequency

Inside the Box

3. A Peek Inside a VFD Control Panel

Alright, let's peek inside the VFD control panel and see what makes it tick. At the heart of it all is, of course, the VFD itself — the Variable Frequency Drive. This is the electronic device that actually manipulates the frequency and voltage going to the motor. It takes standard AC power and converts it into a variable frequency, variable voltage output.

Next, you'll find circuit breakers and fuses. These are your electrical safety nets. They protect the VFD and the motor from overloads and short circuits. If something goes wrong, they trip and cut off the power, preventing damage to the equipment and potentially saving lives. Think of them as the seatbelts of your electrical system. You hope you never need them, but you're sure glad they're there.

Then there's the control wiring. This is the nervous system of the panel, connecting all the components together and allowing them to communicate with each other. It includes wires for power, control signals, and feedback signals. Proper wiring is crucial for reliable operation; a loose connection or incorrect wiring can cause all sorts of problems.

Finally, you'll often find a human-machine interface (HMI). This could be a simple keypad with a few buttons and a display, or a more sophisticated touchscreen. The HMI allows you to set the desired motor speed, monitor the motor's performance, and troubleshoot any problems. It's your window into the world of the VFD, giving you the ability to control and manage your motor with ease.

Applications Galore

4. Where Do VFD Control Panels Show Up?

So, where do you typically find these VFD control panels in action? The truth is, they're incredibly versatile and used in a wide range of industries and applications. Think about any situation where you need precise control over the speed of an electric motor. Chances are, a VFD control panel is involved.

One common application is in HVAC systems. In large buildings, VFDs are used to control the speed of fans and pumps, adjusting the airflow and water flow to match the building's heating and cooling needs. This saves a significant amount of energy compared to running the fans and pumps at full speed all the time. It's like having a thermostat for your entire building's ventilation system.

VFDs are also widely used in manufacturing. They control the speed of conveyor belts, pumps, mixers, and other equipment, allowing for precise control over the production process. This leads to higher quality products, reduced waste, and increased efficiency. Imagine a bottling plant where the speed of the conveyor belt and filling machines needs to be perfectly synchronized. That's where a VFD control panel shines.

Beyond HVAC and manufacturing, VFDs are used in applications like water and wastewater treatment, mining, oil and gas, and even renewable energy systems. They're essential for controlling pumps, compressors, and other equipment in these industries, ensuring efficient and reliable operation. So, the next time you're in a large building, a factory, or even a water treatment plant, take a moment to appreciate the silent workhorse that is the VFD control panel.

Choosing the Right Panel

5. What to Consider when Selecting a VFD Control Panel.

Alright, so you're convinced you need a VFD control panel. Great! But with so many options available, how do you choose the right one? Well, there are a few key factors to consider. First and foremost, you need to make sure the VFD is properly sized for your motor. This means matching the VFD's voltage and current ratings to the motor's specifications. Undersizing the VFD can lead to overheating and damage, while oversizing it can be a waste of money.

Next, think about the environment where the VFD control panel will be installed. If it's a dusty, wet, or corrosive environment, you'll need a panel with a NEMA rating that's appropriate for those conditions. NEMA ratings indicate the level of protection the enclosure provides against various environmental hazards. It's like choosing the right raincoat for the weather — you want something that will keep your equipment safe and dry.

Consider the control features you need. Do you need a simple keypad for basic speed control, or do you need a more sophisticated touchscreen with advanced programming capabilities? Do you need the ability to communicate with other systems via Ethernet or other communication protocols? These are all important factors to consider when choosing a VFD control panel.

Finally, don't forget about safety. Make sure the panel includes features like circuit breakers, fuses, and overload protection to protect your equipment and personnel. Look for panels that are certified by recognized safety organizations like UL or CE. Remember, safety should always be a top priority.

Vfd Control Panel At 90000.00 INR In North 24 Parganas, West Bengal

Frequently Asked Questions (FAQs)

6. Your Burning Questions Answered!

Let's tackle some common questions about VFD control panels.

Q: Can I install a VFD control panel myself?A: While some technically inclined individuals might be tempted, it's generally best to leave the installation to qualified electricians or technicians. VFD control panels involve high voltages and complex wiring, and improper installation can be dangerous. Safety first!

Q: How much maintenance do VFD control panels require?A: VFD control panels are generally pretty low-maintenance. However, it's a good idea to periodically inspect the panel for dust buildup, loose connections, and other signs of wear and tear. Cleaning the panel and tightening any loose connections can help extend its life and prevent problems.

Q: Are VFD control panels noisy?A: Some VFDs can generate audible noise, particularly at certain frequencies. However, most modern VFDs are designed to minimize noise. If noise is a concern, consider choosing a VFD with a built-in filter or installing the panel in a soundproof enclosure.