Painstaking Lessons Of Info About Does A PWM Reduce Voltage

Decoding PWM

1. Understanding Pulse Width Modulation

So, you're pondering PWM, huh? Specifically, you're wondering if it's some kind of voltage-reducing wizard. Well, let's get one thing straight: PWM, or Pulse Width Modulation, isn't about directly lowering the voltage like a dimmer switch. Think of it more as a clever on-off switch that's flipped really, really fast. We're talking thousands of times a second, often more! It's more like a sophisticated illusion.

Imagine a light switch. You can either have it on (full brightness) or off (complete darkness). PWM is like rapidly flicking that switch. If the switch is on for most of the time and off for only a tiny bit, the light appears very bright. If it's off for most of the time and on only briefly, the light appears dim. That rapid switching creates the illusion of reduced voltage because you're averaging out the on-time and off-time.

The magic lies in the 'pulse width.' That's the duration the switch is 'on' during each cycle. A wider pulse means more 'on' time, therefore more power delivered. A narrower pulse? You guessed it — less power. This allows fine-grained control without actually altering the voltage itself. It's all about duty cycle, baby!

Consider a simple example: controlling the brightness of an LED. Instead of using a resistor to directly lower the voltage, which would waste energy as heat, PWM sends the full voltage to the LED but only for a fraction of the time. The LED still receives the full voltage when it's 'on', but the perceived brightness is reduced because it's spending more time 'off'. Efficient, right?

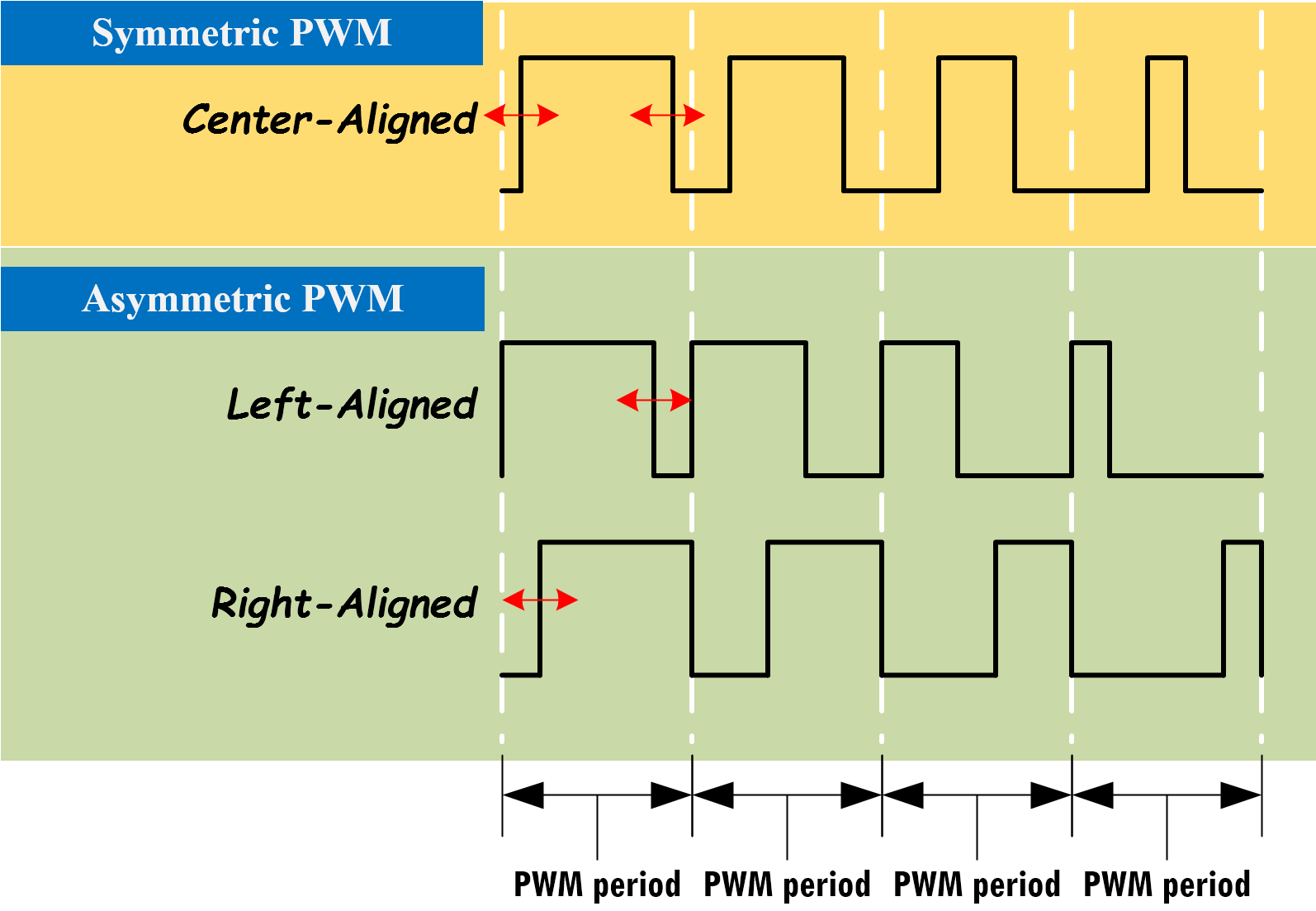

Pwm Techniques In Power Electronics

The Illusion of Voltage Reduction

2. Duty Cycle Demystified

The heart of PWM's voltage-reducing effect is the duty cycle. Simply put, the duty cycle is the percentage of time the signal is 'on' compared to the total time of one cycle. A 50% duty cycle means the signal is on for half the time and off for the other half. A 90% duty cycle? Mostly on! A 10% duty cycle? Mostly off!

If you have a 12V power source and you're using PWM with a 50% duty cycle, the average voltage delivered to your device will be around 6V. Note the emphasis on average. At any given moment, the device is still getting either 12V (when the switch is 'on') or 0V (when it's 'off'). But because it's switching so rapidly, the device responds to the average voltage.

So, while the voltage itself isn't changing, the effective voltage, or the amount of power delivered over time, is reduced. This is why it appears like PWM is lowering the voltage. It's a perceptual trick! It's like those optical illusions where lines appear to be different lengths depending on the surrounding shapes. Your brain is doing some averaging for you.

Think of it like ordering a pizza. If you only eat half the pizza, youve effectively consumed less pizza voltage than if you ate the whole thing. The individual slices (the voltage pulses) are still the same size and deliciousness, but the overall impact is reduced because you didn't consume them all at once. Okay, maybe that's a terrible analogy, but hopefully, it makes the point!

Why Use PWM Instead of Just Lowering the Voltage Directly?

3. The Advantages of Pulse Width Modulation

You might be thinking, "Why not just use a simple voltage regulator and be done with it?" Good question! The main reason is efficiency. Linear voltage regulators, the type that directly reduce voltage, work by essentially "burning off" the excess voltage as heat. This is incredibly wasteful, especially in battery-powered applications. Imagine your phone getting super hot just to dim the screen — not ideal!

PWM, on the other hand, is much more efficient. Because the switch is either fully on or fully off, there's very little power dissipated as heat. It's like a light switch compared to a dimmer. Dimmers get warm because they're resisting the flow of electricity and turning some of it into heat. A light switch is either fully on or fully off, generating very little heat.

Another advantage of PWM is its ability to handle a wide range of voltages and currents. It's a versatile technique that can be used to control everything from the speed of a motor to the brightness of an LED to the volume of a speaker. Its adaptability makes it a cornerstone of modern electronics.

Furthermore, PWM offers precise control. By finely adjusting the duty cycle, you can achieve very granular adjustments in power delivery. This is crucial in applications where precise control is essential, such as robotics, servo motors, and precision lighting systems. It's the key to getting things just right.

Applications Galore

4. Examples of PWM in Action

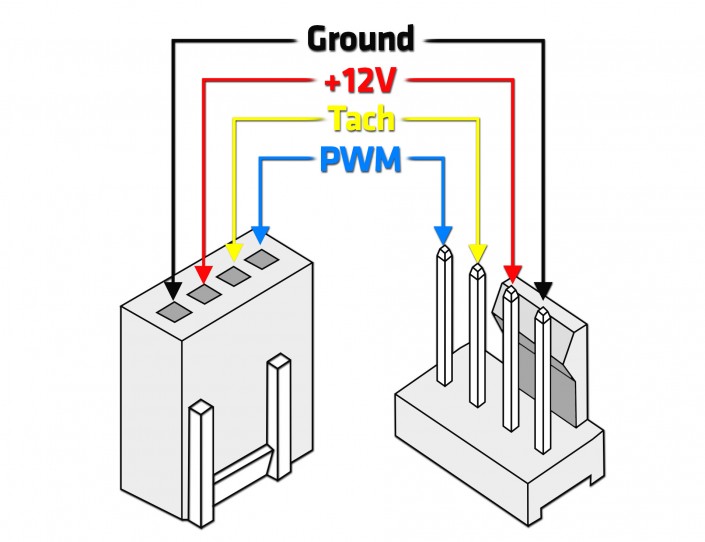

PWM is everywhere! Seriously, it's in more devices than you probably realize. One common application is controlling the speed of DC motors. By varying the duty cycle of the PWM signal applied to the motor, you can precisely control its speed. This is used in everything from electric vehicles to power tools to robotics.

Another widespread use is in LED lighting. As mentioned earlier, PWM is a very efficient way to dim LEDs without wasting energy. It's used in everything from smartphone screens to large-scale LED displays. This is also what allows you to finely tune the brightness settings on your monitor without draining the battery significantly.

PWM is also commonly found in power supplies. It's used to regulate the output voltage of switching power supplies, ensuring a stable and efficient power source for various electronic devices. Its the unsung hero keeping your gadgets powered without exploding.

Even in audio amplifiers, PWM is employed in Class D amplifiers. These amplifiers use PWM to switch the output transistors on and off, resulting in very high efficiency. This is what allows portable speakers and headphones to deliver decent sound quality without consuming a ton of power. Its the reason your tunes dont completely kill your phone battery.

PWM

5. Recap and Final Thoughts

So, let's wrap this up. Does PWM reduce voltage? Not in the literal sense. It doesn't actively step down the voltage like a voltage regulator. Instead, it rapidly switches the voltage on and off, creating the illusion of reduced voltage. It's all about the duty cycle, the percentage of time the signal is 'on' compared to the total cycle time.

This clever technique offers numerous advantages over directly lowering the voltage, most notably improved efficiency. By minimizing power dissipation as heat, PWM is a valuable tool for controlling power in a wide range of applications. It's not magic, but it's pretty darn close!

Remember, it's not actually reducing the voltage, it's just making it seem that way. Think of it as a really fast blinker. If something is only visible half the time, it appears to be less intense. Same principle!

Next time you see a smoothly dimming LED or a precisely controlled motor, remember the unsung hero behind the scenes: PWM. It's the trickster, the illusionist, the averaging master that makes our modern electronics work so efficiently.

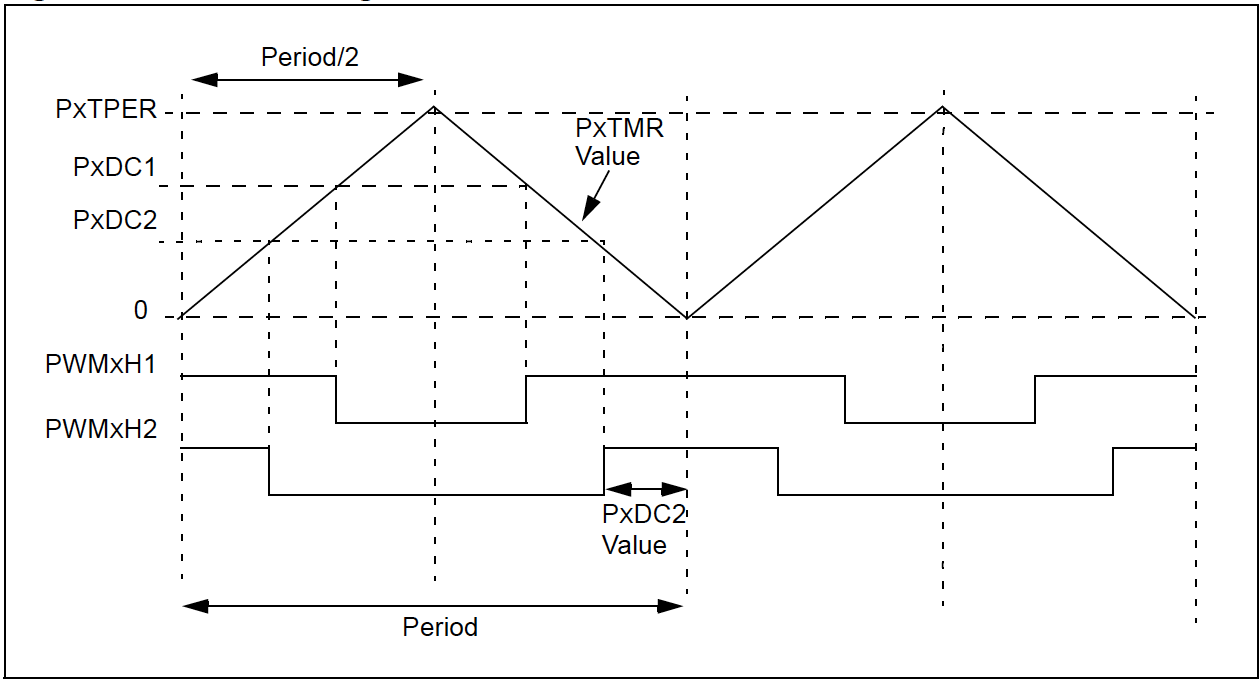

PWM Strategy And Switching Signals Download Scientific Diagram

Frequently Asked Questions

6. Your PWM Questions Answered

Here are some common questions about PWM to clear up any remaining confusion:

Q: Can PWM be used with AC voltage?

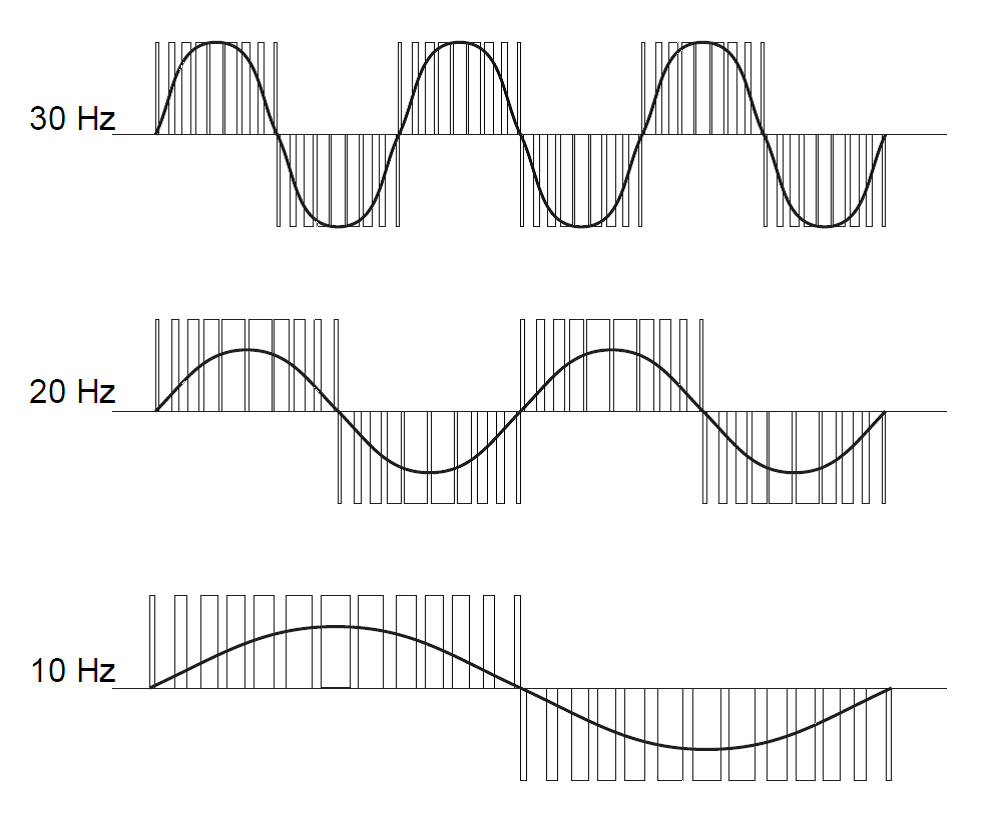

A: Yes, but it's more commonly associated with DC voltage control. With AC, you're essentially chopping up the AC waveform, which has its own set of complexities and considerations. The principles of duty cycle and averaging still apply.

Q: What happens if the PWM frequency is too low?

A: If the frequency is too low, you might start to see flickering in LEDs or hear buzzing in motors. This is because the switching between on and off becomes perceptible. A higher frequency generally leads to smoother performance, but also increases switching losses.

Q: Is there a limit to how high the PWM frequency can be?

A: Yes, there is. As the frequency increases, switching losses become more significant. Eventually, the energy lost during each switch (turning the voltage on and off) can outweigh the benefits of using PWM in the first place. The optimal frequency depends on the specific application and the characteristics of the components being used.

Q: Can PWM damage my electronics?

A: Generally no, PWM won't damage your electronics if implemented correctly. However, it's important to ensure that the PWM frequency is appropriate for the device being controlled and that the voltage and current ratings are within the device's specifications. Improper implementation could lead to overheating or other issues.